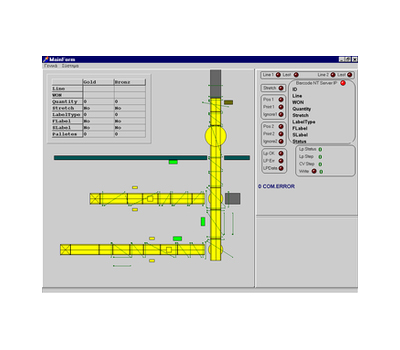

Integrated SCADA solutions

Alpha Motion S.A. offers integrated SCADA solutions comprising of parametrable modules covering all industry requirements.

Tele monitoring – Tele controlling

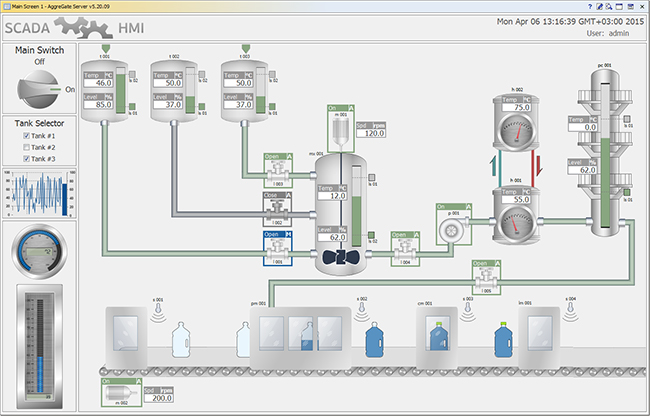

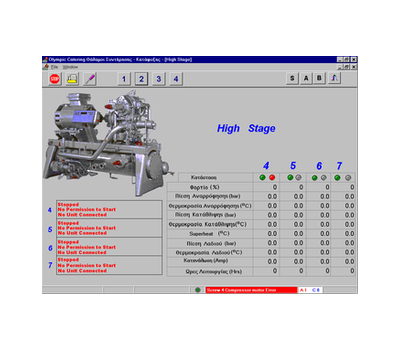

HMI diagrams, icons, instruments, etc. showing the status and the values of any parameter of the installation.

Easy parameters changing.

There is possibility to show more than one window at the same time and also to change the size and adjust the icon to the size of the window. Limitation as to the number of icons and data depends on the memory capability.

Real time events and alarms

HMI diagrams, icons, instruments, etc. showing the status and the values of any parameter of the installation.

Real time events and alarms history

Real time events and alarms history with timing synchronization and acknowledgement per category and time priority.

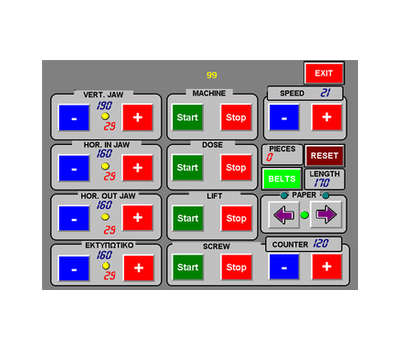

Operation parameters

Possibility of changing operation parameters in production line (for example: times , setpoints, etc.) received by different PLCs

Recipes

Possibility of setting up production lines from different PLCs and parameter groups depending on the product, etc.

Time counting – Preventive Maintenance

Operating time recording and monitoring of up to 16 setpoints per point for preventive maintenance. Special modules for pump change-over procedures.

Recording

Possibility of analog and digital recording and demonstration in graphs and parameter list (and printing)

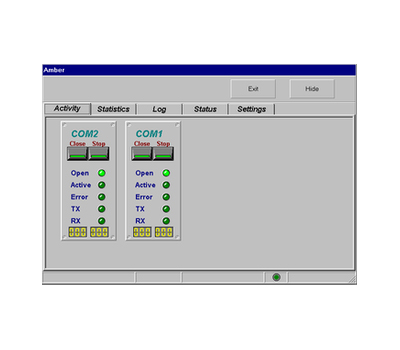

Communication servers

Unlimited communication modules for PLC and control systems per application can be supported from standalone PLCs or industrial networks for different protocols and different manufacturers at the same or different PC or PC network.

All network communications in the market

PLCs:

SIEMENS (MPI, PPI,3964(R), RK512) , TELEMEKANIQUE MODBUS, (ASCII, RTU), MATSUSHITA ,FACON

FieldBus:

CanBus, Profibus, Profinet, EtherCAT, EPL (Power Ethernet)

Refrigaration Controllers / Units :

CAREL MODBUS, SABROE

Motion Control and Drives :

DeltaTau (EtherCAT, EPL), Baldor (EPL, CAN open), Kollmorgen (EtherCAT, CAN open), Parker (EPL, CAN open), Yaskawa (EtheCAT, Mechatrolink II) Siemens (Profibus, Profinet)

Applications