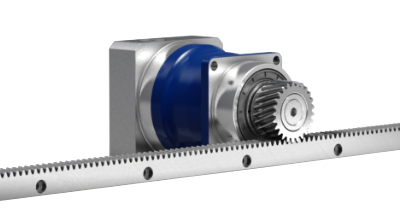

Turn-key solutions using racks – pinions

Weight and space-saving mounting method through compact gear reducer design with integrated pinion

All mounting surfaces ground to tight tolerance – results in flexible mounting options

optimized smooth and low noise level due to pre-assembled gear pinion units with helix angle (19° 31′ 42″. Pressure angle 20°) and high concentricity (RTP version < 10 µm)

High reliability because of wear-resistant surface treatment and individually deburred gear teeth

Compact, optimized design with low mass moments of inertia results in maximum possible feed dynamics with short acceleration times

Maximum precision for lifting axes through positive connection of pinion

Maximum operational safety because of high overload capacity

Quality 5 (AGMA-11) through permanent checks according to DIN 9001

Ultra-high linear accuracy because of minimum total pitch error (12 µm / 500 mm)