Kollmorgen Automation Suite™

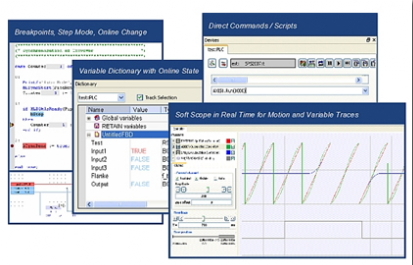

KAS (Kollmorgen Automation Suite™) is an integrated set of tools and components that help the automation system designer build high- performance machines.

Software

Features:

Benefits:

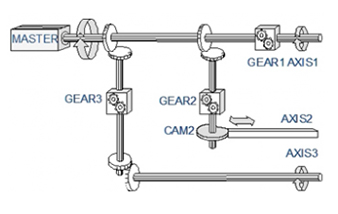

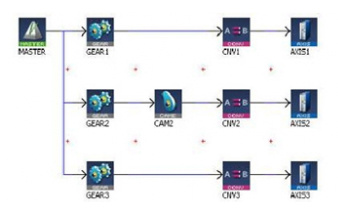

Pipe Network™

Features:

Benefits:

PLC Open for Motion

In addition to our breakthrough Pipe Network™, Kollmorgen Automation Suite™ includes PLCopen for motion, giving developers the choice of programming in a familiar environment that leverages existing engineering resources.

Focused around IEC 61131-3, PLCopen for motion is a structured programming method for creating motion applications that are hardware -independent, interoperable, and scalable across different control solutions and architectures.

Features:

Benefits:

Hardware

Panel PAC Controllers

Our Enhanced Performance Panel Programmable Automation Controller (Panel PAC) offers mid-range computing performance, delivering the highest processor performance with Intel Celeron processor technology. It includes your choice of a 10″ or 15″ integrated display. Our High Performance Panel PAC offers premier computing performance for processor technology up to the Intel Core 2 Duo family, and includes your choice of a 15″ or 17″ integrated display.

Performance Box Controllers

Our Performance Box Controllers offer the flexibility to separate your HMI display from the controller unit. With a variety of CPU and memory choices, plus a reliable flash drive for storing the pre-installed software and your application programs, these controllers are fully equipped and ready for operation right out of the box to help speed your time to market.

AKD PDMM™ Programmable, Multi-Axis Master Drive – Controller

The AKD PDMM™ combines one AKD servo axis and a master controller that supports up to seven or more additional AKD axes in a single, compact package.

It provides integrated control for multiple high-performance axes, complete I/O and HMI interfaces, and includes the full automation capabilities of Kollmorgen Automation Suite™ giving you a single, scalable development environment for both AKD PDMM and PAC-based machines.

Features:

* Maximum axis count depends on motion/automation complexity and performance (8 axes nominal based on medium complexity at 4 kHz network update rate)